A Heartfelt Thank You

Client Needs Understood

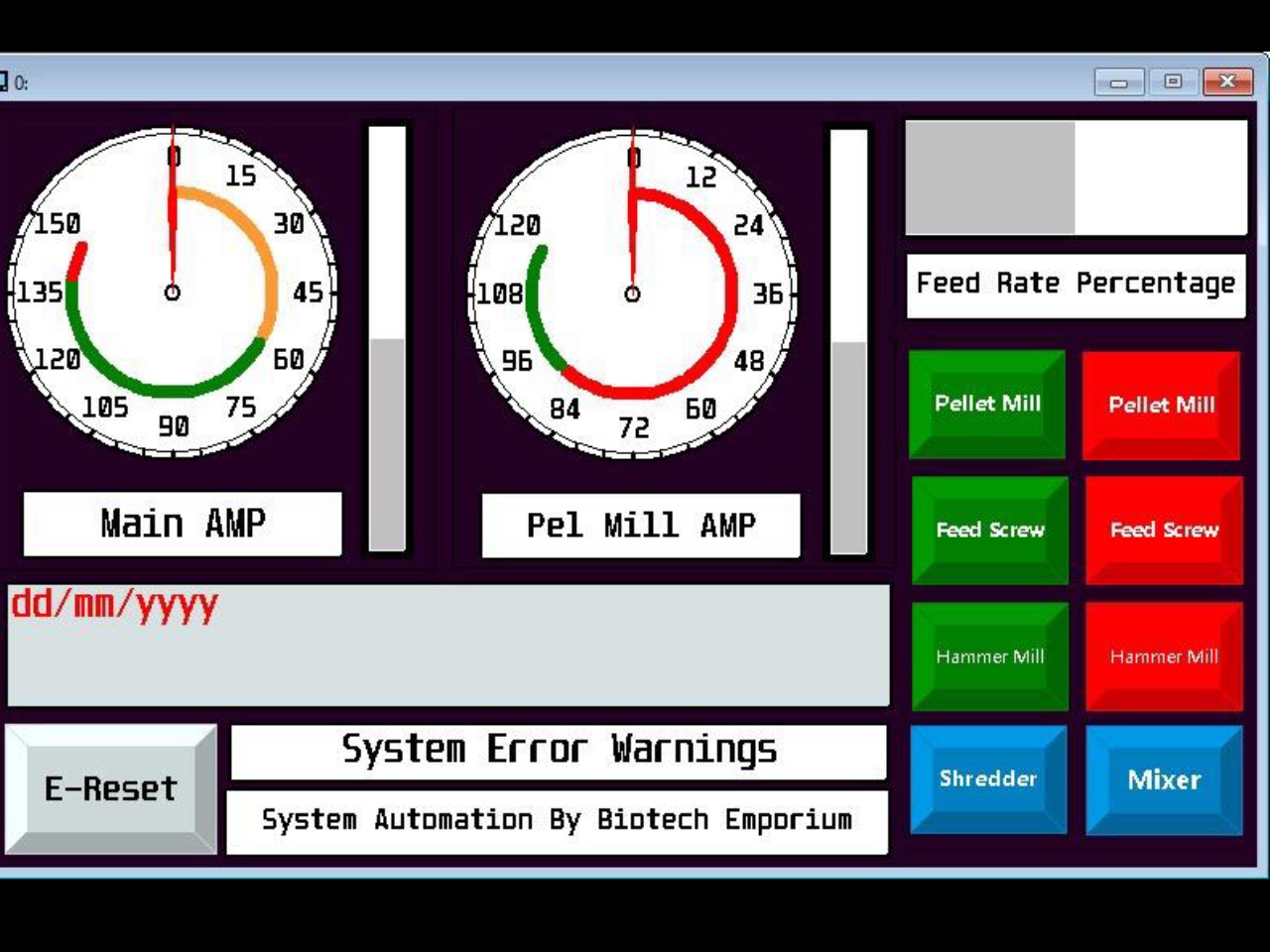

The client in this project came to us with a frustrating production bottleneck. His feed plant was limited by a 100 kVA Eskom supply that couldn’t be upgraded, while the plant required 164 kW of installed power.

This mismatch meant he could only run one section of the plant at a time, forcing the rest of the operation to wait. His pellet mill, the core of his operation, barely managed 800 kg per hour, and even then, only for four hours a day because the rest of the plant couldn’t keep up.

2 Week Site Inspection

Breaking the Project into Phases

Zero Downtime Ensured

We broke the project into phases because the client had orders to fill, and it was critical that our work caused zero downtime. Every step was carefully planned to fit around his production schedule. Once complete, the client will be able to run all processes simultaneously, eliminating downtime and boosting output. Increased production and savings from phases one and two will cover the costs of phases three and four, making the entire upgrade self-sustaining.

Phase One Results

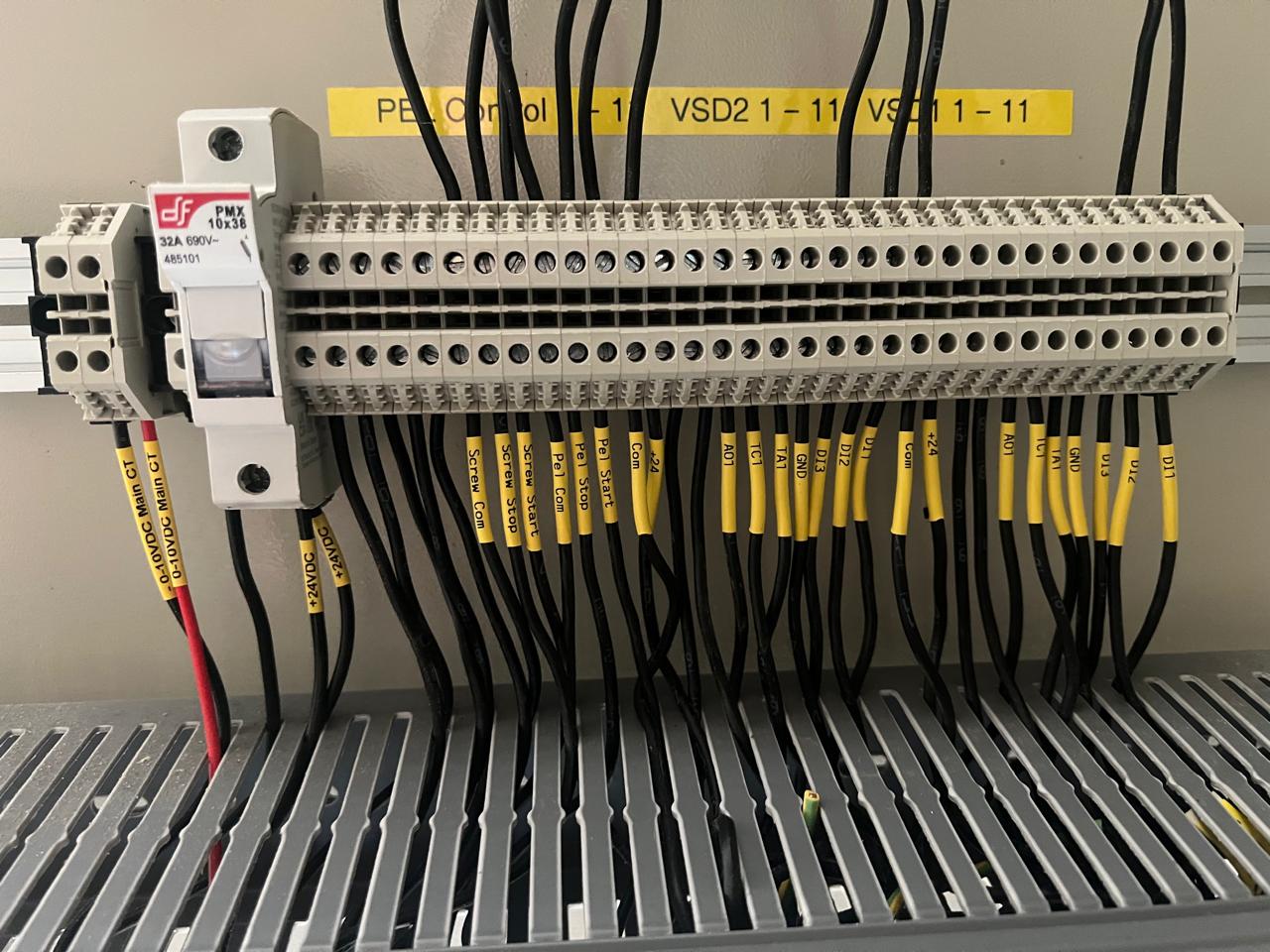

Key Upgrades Included

Outstanding Results

Phase Two in 2025